Who we are

Sawquip International

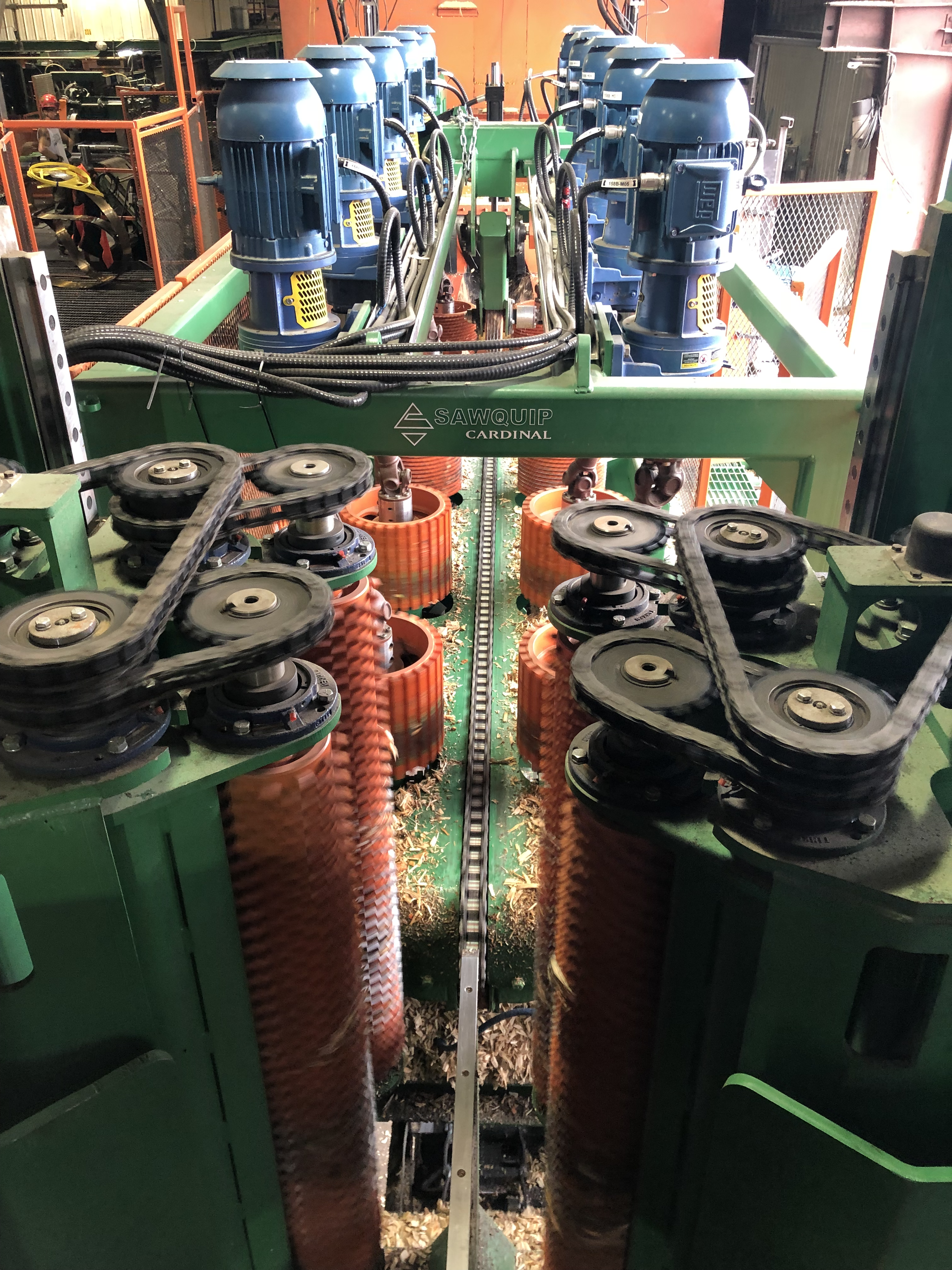

Sawquip International is a well established and recognized manufacturer of technically advanced sawmill equipment which it conceives, designs and fabricates for the primary and secondary breakdown of logs into quality lumber products. Its sawmill equipment is found in North American and offshore markets.

Since October 2017, Sawquip is part of the Cardinal family. By joining their forces, both companies are able to offer a full range of products in order to meet the specific needs of their customers.

Cardinal specializes in the design, manufacturing and distribution of equipment used in the sawmill, forestry, recycling, mineral exploration, and mining.

Sawquip International

For further information regarding products and services offered by Sawquip in the sawmill, and mining industries, contact us!

Sawquip International

Our Expertise

Sawquip International

Our Products

The use of chipping heads is the most efficient, high production rate of primary log breakdown. Chipping heads can be configured as two vertical with an optional bottom head and can have face mounted saw teeth for smooth surfaces. Thin kerf guided circular saws in twin or quad configuration are close coupled to the chipping heads to produce two or four side cuts that are discharged towards the board edger. Centre two face cants go forward for further processing.

When processing cants produced from primary log breakdown, you must take into account the form and curvature of a cant. For two sided cants, you must chip the rounded sides to eliminate slabs and use thin kerf saws to breakdown the cants into lumber.

Side cuts from primary log breakdown have two rounded sides (unless a profiler is used) which requires removal or “edging”. To eliminate long small pieces, Sawquip has developed chipping edgers which chip the sides to proper board width.

Sawquip has developed equipment that when combined, can automate log and cant breakdown often in a single pass. Multi-function equipment can be used for primary and secondary breakdown as well as edging.

Sawquip International

Oceania

Be part of our team!

You want to be a part of a young and dynamic team that is not afraid of challenges?

Available jobs

Learn more